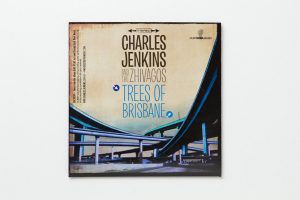

CD Printing

Once you have asked yourself questions to determine the type of CD printing you need, you can go ahead and loo into them in more detail. For example, how many CD’s do you need printed? What is the intended use of the product? What artwork is needed for the discs? Let’s look at two types of CD printing in more detail;

Digital CD Printing

This CD printing method uses a printer that employs the same process as an inkjet printer that many home users will be familiar with. In fact, many home printers can be equipped with a CD printing tray for use with pre-manufactured CDRs with a printable surface. A company printing CDs professionally will most likely be using an inkjet printer that is specifically for the printing of CDs. These printers have an auto-loading mechanism enabling the unattended printing of up to 200 CDs. The printer automatically loads unprinted discs and unloads the finished discs onto separate spindles.

Digital CD printing using one of these printers is slow but there are no fixed set up costs involved. This is fine if the order quantity of discs is less than 100, or 200 if there is no fixed, imminent deadline for the order.

This method of printing is capable of producing highly professional looking CDs as an inkjet printer can print at very high resolutions. The printed surface does need protection though and a layer of clear lacquer needs to be applied to the discs to prevent moisture coming into contact with the ink through handling or exposure to damp environments. This necessity adds significantly to the overall project time. Printable discs are available which have a specially formulated surface that becomes water resistant after printing but they are more expensive than regular printable discs and so a decision has to be made depending upon the urgency of the project; extra expense for water resistant discs or extra time for the application of a layer of clear lacquer?

CD Screen Printing

CD Screen printing is ideal for artwork designs that involve solid areas of colour. Screen printing is carried out using a machine with a rotating bed that has 5 separate stations where a different colour of ink can be applied. The CDs can have a base colour applied first over the whole disc area, which means that a screen printed CD design can consist of a total of 6 different colours maximum.

As the process name suggests the screen printing is applied through the use of very fine mesh screens. There is a separate screen for each colour in the artwork design. To create a screen, a film is produced which has the areas where ink is not to be applied to the disc, blacked out. The new screen is initially coated with a thermal emulsion. The film and the screen are aligned on top of each other using guide marks and are put into an exposure unit. When the screen is exposed to a hot, bright light, the area of thermal emulsion not protected by the dark area on the film is cured. The screen is then washed with a water spray and the areas of uncured emulsion wash away to reveal the mesh.

The screen is then fixed at its station. Once all the screens have been prepared in this way, the printing can begin. The CDs are loaded onto the machine by an automated robotic arm system. They are placed into a platen which holds the disc firmly in position. At each station, ink is added on top of the mesh screen and a rubber squeegee blade passes over the top pressing the mesh down onto the disc surface and forcing the ink through the fine mesh holes and onto the surface of the disc. The ink application stroke takes about a second and each station applies ink to a disc simultaneously as soon as the first 5 discs have been fed into the system. This speed means that a screen printing machine can print more than 3500 discs in an hour so large orders can be completed quickly.

There are, however, significant fixed set up costs due to the requirement for screens and films. These can be reduced by limiting the artwork to fewer colours, with a single colour print onto a silver disc being the most cost effective print. The fixed costs do mean that this CD printing process is only really viable for orders of over 100 discs.

The CD screen printing process is capable of producing a truly amazing CD print at a very high resolution due to the use of extremely fine mesh screens. It is not ideal, though, for printing photographic images due to the presence of subtle colour gradients in these images. What makes the screen printing process truly unique is the availability of fluorescent and metallic inks which can really add a WOW factor to your CD print.

To sum up your options;

- If you only need a short run of less than 100 discs, digital printing will be the most cost effective CD printing method. There is certainly no compromise with print quality but there are no fixed set up costs.

- If your image consists of 1 or more solid colour areas, then screen printing is the CD printing method to choose for a pin sharp result. Fluorescent and metallic artwork also requires screen printing.