For processing CD duplication one of the best methods is to use the DVD-R or CD-R format as both these formats offer great compatibility. They include the latest features from SONY, Pioneer, NEC, etc. and have a high standard of professional and fast duplication. If you are looking for such professional service you can check out CD duplication Sydney.

CD duplication is not a very complicated process and it can be performed on your home computer also. A special programme on the computer helps to automatically copy the pertinent content on a CDR which is pre-manufactured. The method is very simple and is mostly used when only a small quantity of CDs need to be duplicated. The person operating the computer needs no special training.

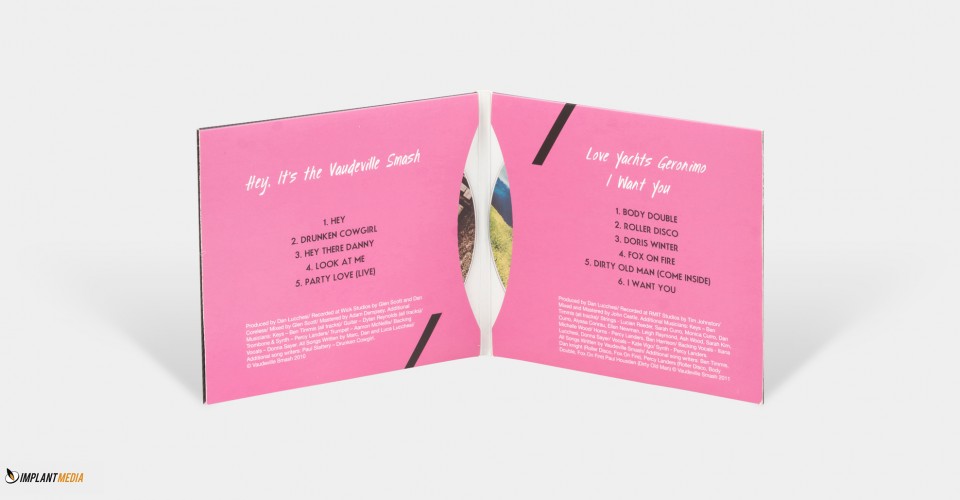

Method of Printing

A service like CD duplication Sydney has a set process for printing CDs. Once the data is copied on the disc, it becomes ready for printing. Then the graphics section ascertains that they will be able to print a high quality image. By using the services of CD duplication Sydney, you will have a quality product which has been proofed, checked and approved.

The process starts as under:

- The customer provides a CD-ROM for duplicating to CD duplication Sydney This CD-ROM content is checked to ensure it meets ISO standards as only then will it provide the right quality, precision and good data reproduction.

- CD duplication Sydney service then creates a master made of glass which has a photo-sensitive layer. All of the customer’s information is then engraved on this master glass with the help of a laser light. As a safety security, CD duplication Sydney service engraves a special IFP number on each disc of glass that it produces. The next step involves application of a fine coat of silver by vacuum evaporation.

- Once the master glass is ready it is transformed to a mould; a nickel layer is added through electrolysis. The next step involves the removal of the nickel layer from the glass so the CD negative can be recovered. This negative is known as the stamper of the CD and by repeating the above steps, more masters can be made and the whole process repeated.

- Once the mould is ready, liquefied polycarbonate is injected in the mould. Within a few seconds a CD is created containing the required data.

- To be able to read the CD it has to be covered with a thin micro layer of vacuum laid aluminium. This surface of aluminium plays the role of a mirror which helps to reflect back the laser light to enable the information to be read.

Once the CD is ready it has to be protected from dangers such as scratching, dropping and bending. To protect this from happening, it is varnished, sealing the CD from such mishaps. The last phase of making the perfect CD is the printing of the label. This can be done either through offset printing or silk screen printing, in different colours.